Dredging Equipment & Solutions

Our Equipment

At Minnesota Dredge, we take pride in operating a full range of industrial dredging equipment in Minnesota sourced from the industry’s most trusted brands — EDDY Pump, HAWK Excavator, and DAE Pumps. Our fleet includes cutterhead dredge equipment, hydraulic excavator pump attachments, remote-operated dredges, and dewatering systems engineered for performance, reliability, and efficiency. Every unit is built for heavy-duty use in ponds, rivers, lagoons, and industrial sites, ensuring productivity even under Minnesota’s toughest dredging conditions.

Excavator Pump Attachments

The EDDY Pump Excavator Pump Attachment turns a standard excavator into a high-performance dredging system. Ideal for slurry pumping, sediment removal, and dewatering applications, this powerful attachment for excavators delivers unmatched suction and solids-handling capabilities.

Available in both hydraulic excavator pump attachments and electric-powered versions, these systems are built for flexibility and field efficiency. Designed to minimize clogging and downtime, the EDDY Pump attachment ensures long-lasting durability and maximum output, making it one of the most reliable dredging tools in the industry.

Excavator Pump Attachment Specifications

Flow Capacity

700–4000 GPM (up to 350 cubic yards per hour)

Extended Reach

Long reach dredge boom with dredging depths up to 85 feet

Pump Sizes

Available in 4-inch, 6-inch, 8-inch, 10-inch, and 12-inch configurations

Cutting Options

Equipped with a cutterhead for compact material dredging

Water Jetting Ring

Optional feature for material breakup and agitation

Liner-Safe Design

Ideal for dredging over clay, poly, or concrete liners without damage

Head Types

Choice of cutterhead or non-clog dredge head setups

Power Configurations

- Hydraulic (via excavator)

- HPU – Hydraulic Power Unit

- Electric drive option

Precision Control

Integrated RTK/GPS positioning system for accurate dredging and tracking

Product Features

Non-Clogging Design

Engineered to handle large solids without blockages for uninterrupted operation.

High Solids Handling

Efficiently processes dense slurries and debris-laden materials.

High Viscosity & Specific Gravity Capability

Performs reliably in thick, heavy-duty slurry environments.

Superior Abrasion Resistance

Built to endure highly abrasive materials, extending equipment life.

No Critical Tolerances

Simplified design reduces wear points and the risk of mechanical failure.

Low Maintenance Requirements

Minimal servicing needed, ensuring long-term dependability.

Reduced Downtime

Streamlined operations minimize delays and boost overall productivity.

Low Ownership Costs

Durable construction and efficient performance lower total lifecycle costs.

Dredge Sled Systems

The Dredge Sled from EDDY Pump offers an efficient, cost-effective solution for shallow-water sediment removal. This pond dredging sled and lagoon dredging sled system is ideal for restoring water depth, improving clarity, and maintaining aquatic balance.

Engineered for smooth operation in confined areas, the Dredge Sled can handle heavy sludge and fine sediment without damaging liners or pond structures. It’s the go-to choice for environmental, agricultural, and industrial projects that require precision dredging with minimal disruption.

Applications

- Dredging: Ideal for use in lakes, canals, lagoons, ponds, rivers, and waterways for sediment and sludge removal.

- Mining: Effective for process ponds, tailings ponds, and heavy metal recovery operations.

- Wastewater Management: Suitable for sedimentation ponds, settling tanks, and digester tanks to maintain system efficiency.

- Energy Sector: Designed for power stations, oil refineries, and fly ash removal in energy production facilities.

- Industrial & Manufacturing: Perfect for chemical storage ponds, dewatering applications, and general industrial slurry management.

- Agriculture: Supports lagoon dredging, pond cleaning, dam maintenance, canal desilting, and other agricultural water management needs.

Cable-Deployed Dredge Pumps

Our EDDY Pump Cable Deployed Dredge Pumps provide a reliable solution for dredging in hard-to-reach or deep-water locations. Available as cable-deployed hydraulic dredge pumps or cable-deployed electric dredge pumps, they deliver strong suction power and consistent flow over long distances.

These systems are designed for efficiency and durability, handling high-solids content and abrasive materials with ease. Perfect for barge operations, reservoirs, or sediment ponds, these pumps ensure high productivity with minimal maintenance — essential for contractors and industrial operators alike.

Typical Applications

Canal Dredging

Efficiently transfers high-solid slurries and materials from barges and hoppers.

Deep Water Dredging

Ideal for operations requiring extended depth capabilities and precision control.

Mining

Handles slurry transport, tailings removal, and mineral recovery with high efficiency.

Sand & Aggregate

Perfect for sand mining, aggregate extraction, and pit reclamation projects.

Oil & Gas

Supports subsea dredging, sediment removal, and pipeline trenching for offshore and onshore sites

Fly Ash & Coal Ash

Designed for power plant applications involving ash pond dredging and residue management.

Deployment Options

Crane

Easily deployed using a crane for precision placement in deep or confined areas.

A-Frame Barge

Ideal for controlled deployment and retrieval from barges during large-scale dredging projects.

Excavator

Can be mounted and operated directly from an excavator for flexible, site-specific dredging operations.

Diver-Operated Dredge Pumps

For precise underwater dredging, our EDDY Pump Diver-Operated Dredge Pumps are the ultimate solution. These compact, portable systems are available in both Diver-Operated Hydraulic Dredge Pumps and Diver-Operated Electric Dredge Pumps, ideal for targeted sediment and debris removal.

Built to handle high-viscosity materials, these pumps allow divers to reach confined areas where traditional dredges cannot. With their rugged design and clog-resistant technology, they’re trusted for underwater maintenance, marina cleaning, and environmental sediment recovery.

Pump Features

- Non-Clogging Design: Built to handle tough slurry applications without blockages or flow interruptions.

- High Solids Handling: Capable of pumping large solids, ensuring efficient material transfer in demanding environments.

- High Viscosity & Specific Gravity Performance: Designed to move thick, heavy slurries with ease and consistency.

- Abrasion Resistance: Engineered with durable materials to withstand high-wear, abrasive conditions.

- No Critical Tolerances: Simplified internal design minimizes wear and eliminates precision alignment issues.

- Low Maintenance: Requires minimal servicing, reducing labor and maintenance downtime.

- Minimal Downtime: Rugged construction ensures continuous operation and greater equipment uptime.

- Cost-Efficient Operation: Long service life and durable components lower overall ownership and operating costs.

Diver Dredge Overview

- Available Sizes: Commonly offered in 4-inch and 6-inch diver dredge configurations.

- High Solids Capacity: Capable of pumping 40–60% solids efficiently.

- Multi-Diver Operation: Supports one, two, or three divers working simultaneously for increased productivity.

- Extended Reach: Operates with over 300 feet of suction hose for versatile underwater access.

- Long-Distance Pumping: Achieves pumping distances exceeding 2,500 feet, ideal for large-scale projects.

- Power Options: Available in both electric and hydraulic configurations to suit various site requirements.

Self-Priming EDDY Pump Advantages

EDDY Pump Technology

Delivers the power and performance of the EDDY Pump in a convenient self-priming configuration.

Automatic Priming System

A secondary vacuum pump provides continuous, reliable priming during operation.

High Efficiency

Functions like a large industrial wet vac, capable of moving 30–70% solids with ease.

Flexible Power Options

Available in electric or diesel-driven setups to meet diverse project needs.

Non-Clog Design

Handles high-viscosity, high-specific-gravity, and abrasive slurries without clogging.

Rugged Performance

Efficiently processes rags, string, rocks, and debris that typically jam conventional pumps.

Versatile Mounting Configurations

Offered in skid-mounted, trailer-mounted, or stationary systems for flexible deployment.

Self-Priming Slurry and Dredge Pumps

EDDY Pump’s Self-Priming Slurry Pumps combine heavy-duty performance with easy operation. Designed for maximum uptime, these self-priming dredge pumps eliminate the need for manual priming and are available in self-priming electric dredge pumps and diesel-powered configurations.

These self-priming pump systems handle viscous, abrasive, and high-specific-gravity materials with ease. Whether used for slurry pumping, sediment transport, or industrial dewatering, they deliver consistent power, low maintenance, and superior reliability.

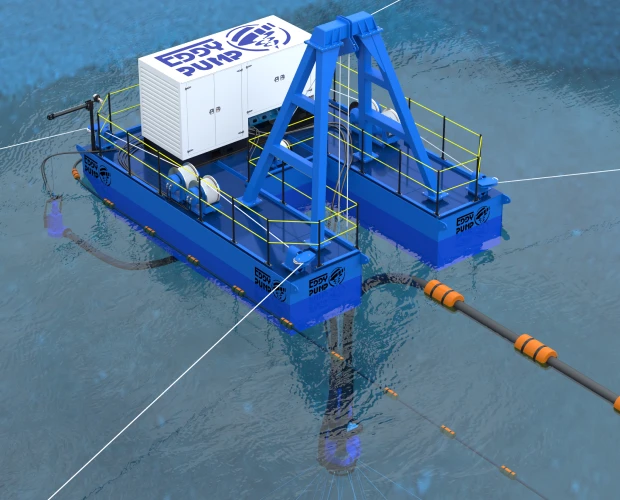

Remote Operated Dredges

The EDDY Pump Remote-Operated Dredges are cutting-edge systems built for safety, precision, and automation. These remote-control dredging equipment solutions allow operators to manage dredging tasks from a distance while maintaining accuracy and throughput.

As part of our advanced remote dredging solutions, these systems integrate GPS guidance and automation for consistent depth control and optimized sediment removal. Engineered for performance and safety, they’re perfect for projects requiring efficient dredging in hazardous or restricted environments.

EDDY Pump Advantages

Remote & Autonomous Operation

Fully remote-operated dredge system designed for precision, safety, and efficiency.

Non-Clogging Performance

Handles high-viscosity, high-specific-gravity, abrasive, and low-pH materials without clogging.

High Solids Capability

Pumps 40–70% solids by weight, ensuring superior material handling in demanding conditions.

Large Object Handling

Can move solids and debris up to 12 inches in diameter with ease.

American Engineered & Manufactured

Proudly 100% built in the USA, ensuring reliability and long-lasting performance.

Cutting-Edge Technology

Developed in state-of-the-art research and development facilities for maximum innovation.

Exceptional Debris Processing

Easily handles rags, string, rocks, and foreign materials that often cause issues in conventional dredging systems.

Pump Features

Non-Clogging Design

Engineered to prevent blockages, allowing continuous pumping of challenging slurries.

High Solids Capability

Efficiently moves materials with high solid content for demanding dredging operations.

Handles High Viscosity & Density

Designed to pump fluids with high viscosity and specific gravity without performance loss.

Abrasive Material Resistant

Built with durable components to withstand highly abrasive environments.

No Critical Tolerances

Simplified internal design reduces wear, ensuring consistent reliability over time.

Low Maintenance Needs

Requires minimal upkeep, reducing labor and service costs.

Minimal Downtime

Robust construction ensures steady operation and increased uptime.

Cost-Effective Ownership

Long-lasting performance and reduced maintenance help keep total ownership costs low.

Long Reach Arm Kit Includes

- Boom: 1 unit – built for extended reach and heavy-duty operation.

- Stick: 1 unit – precision-engineered for stability and control.

- Hydraulic Bucket Cylinder: 1 high-quality unit for smooth, powerful movement.

- Hydraulic Tubing with Clamps: 1 complete set for secure and efficient fluid transfer.

- Hydraulic Pressure Hose: 1 set designed for durability and leak-free performance.

- Bucket Linkage with Pins: 1 complete set for reliable bucket articulation.

- Bucket Pins: 2 pieces – hardened and machined for maximum strength.

- Arm Cylinder Pin: 1 piece – ensures secure and stable connection.

- Yoke Pin: 1 piece – precision-fit for consistent alignment.

- EM Bushings: Heavy-duty bushings for extended component life.

- CE Bucket with Teeth: 1 unit – high-strength digging bucket for efficient material handling.

- Seal Kit (Hydraulic Bucket Cylinder): 1 set – complete sealing solution for hydraulic integrity and performance.

Earth Moving and Positioning Equipment

Our earth-moving equipment from HAWK Excavator includes high-capacity machines equipped with Long Reach Excavator Kits and amphibious undercarriages. These systems are engineered for superior reach, stability, and precision in dredging, excavation, and canal maintenance.

Paired with HAWK Vision RTK GPS Positioning Systems, operators can achieve precise digging and grade control with real-time accuracy. This combination of advanced technology and durable equipment ensures exceptional results in every earthmoving and dredging application.

Dewatering Pumps and Systems

We utilize DAE Pumps Dewatering Equipment for efficient fluid and sediment removal in construction, mining, and dredging operations. Our selection includes submersible dewatering pumps and selfpriming dewatering pumps built for high solids handling and consistent performance.

These pumps are engineered for non-clogging operation and durability, making them ideal for handling stormwater, slurry, and groundwater management. DAE Pumps delivers dependable dewatering solutions that ensure minimal downtime and maximum efficiency across every site.

Frequently Asked Questions

What dredge contracting services do you offer in Minnesota?

We provide a full range of dredge contracting services in Minnesota, including river dredging, lake dredging, canal dredging, coastal restoration, and environmental sediment removal. Each project is tailored to meet local regulatory, environmental, and operational requirements.

Do you offer marine dredge contracting services in Minnesota?

Yes. Our marine dredge contracting services in Minnesota cover ports, harbors, and coastal waterways. We handle sediment removal, channel deepening, and shoreline protection with precision and compliance.

What’s included in your harbor dredging contracting services?

Our harbor dredge contracting services in Minnesota include sediment removal, depth restoration, and debris clearance. We ensure navigational channels remain safe and operational for both commercial and recreational vessels.

Do you handle river and canal dredging projects?

Absolutely. We specialize in river and canal dredging contracting services in Minnesota, focusing on restoring water flow, preventing flooding, and maintaining navigable depths for transportation and irrigation systems.

Can you assist with environmental and maintenance dredging?

Yes. We provide environmental dredging contracting services to remove contaminated sediments and maintenance dredging to prevent silt buildup in harbors, lakes, and reservoirs.

Do you offer coastal and lake dredging services?

We do. Our coastal and lake dredging contracting services in Minnesota support beach nourishment, shoreline stabilization, and sediment control to protect ecosystems and coastal infrastructure.

What equipment do you use for dredge contracting projects?

We use advanced hydraulic dredging systems, self-priming slurry pumps, and remote-operated dredges designed for reliability and environmental safety. Each setup is customized for site conditions and project scope.

How do you ensure environmental compliance in dredging operations?

Our team adheres to all state and federal environmental guidelines. We use eco-friendly dredging methods, turbidity-control systems, and silt containment to minimize ecological impacts and protect aquatic habitats.

Why should I choose Minnesota Dredge over other dredging companies?

With nearly three decades of experience, Minnesota Dredge stands out for its proven track record, advanced equipment, and strong compliance with permitting and QA/QC standards—ensuring reliable results in every project.

How can I get a consultation for my dredging project?

You can contact our experts through our website or call our project team directly. We’ll conduct a comprehensive site evaluation, recommend the appropriate dredging approach, and prepare a detailed project proposal tailored to your goals and site conditions.